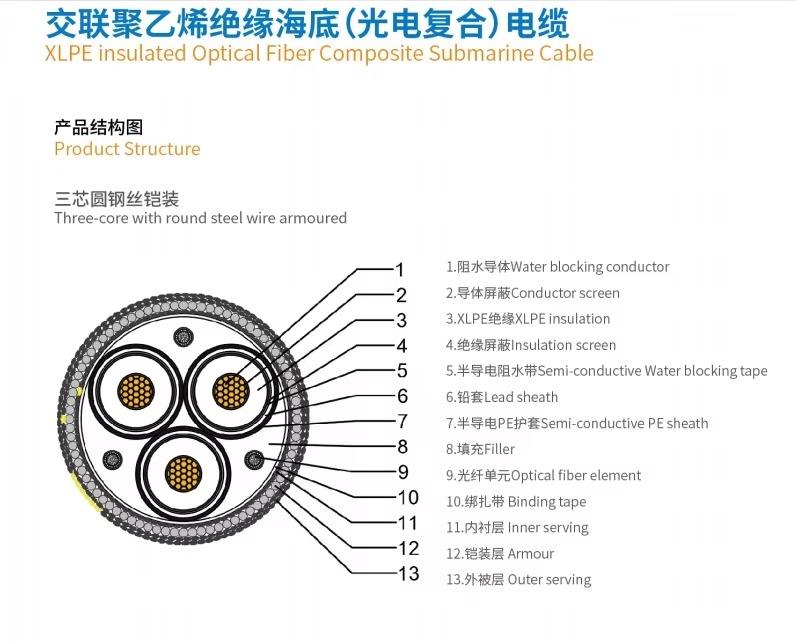

XLPEinsulated Optical Fiber Composite Submarine Cable

The main uses of submarine communication cables include international communications, network interconnection, data

transmission, scientific research and energy interconnection.

XLPEinsulated Optical Fiber Composite Submarine Cable

The specifications of submarine communication cable mainly include insulation material, core structure, sheath material and

other specific parameters. Here's how:

1. Insulating materials: submarine communication cables are usually wrapped with insulating materials, to prevent the leakage

of current and ensure the safe transmission of the cables. insulation materials should have good electrical insulation

properties can withstand long-term immersion in water and high pressure environment.

2. Core structure: the core wires inside the cable are usually wrapped in layers with an anti-torsional structure, to reduce

the wear and break of the core wires when the cable is bent or moved. The core wire may be composed of multiple conductors,

each conductor is insulated from each other, to achieve multi-channel signal transmission.

3. Sheath material: sheath material should have good waterproof and corrosion resistance, to protect the internal structure of

the cable from the erosion of sea water and Marine life. The commonly used sheath materials include seawater resistant PE and

imported seawater resistant PUR material, these materials have good low temperature resistance, can work statically for a long

time in extreme underwater environment.

4. Shielding structure: In order to reduce electromagnetic interference, cable adopts tin-plated copper wire braid copper mesh

shielding, density reaches more than 85%, further enhance the anti-interference ability of the cable.